VODKA USE SUPER FLINT GLASS 750ML BOTTLES BULK SALE

| PRODUCT NAME | VODKA USE SUPER FLINT GLASS 750ML BOTTLES BULK SALE |

|---|---|

| REFERENCE | HK-004 |

| GLASS COLOURS | SUPER FLINT / EXTRA WHITE FLINT |

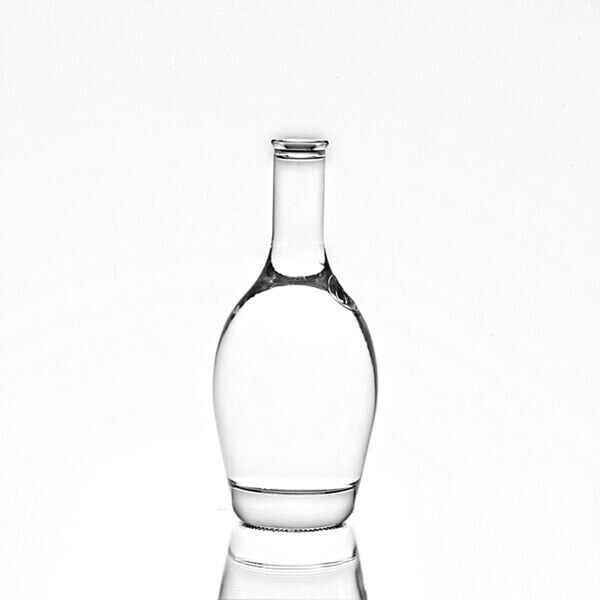

| BOTTLE SHAPE | Round Shape |

| FINISH | Wooden Cork |

| ENTRANCE BORE DIAMETER | 21.5 mm |

| GLASS BASE THICKNESS | 20.2 mm |

| BOTTLE HEIGHT | 273 mm |

| LENGTH | 108.3 mm |

| Weight | 680g |

Description

750ml bottles bulk sale by HIKING GLASS. Extra white flint glass, the first grade quality in factory direct sale price. This model HK-004 has a cute shape, the thin neck and fat belly, looks funny. There is embossed logo in the front side to show the exclusive right for this bottle. It comes with a wooden cork, plastic stopper also available.

DETAILS of 750ml GLASS BOTTLE

Decoration Application

- Decal and print logo on 750ml glass bottles, OEM is highly welcome.

- Frost glass bottles are becoming popular for vodka bottles.

- Embossing is widely used for customized glass vodka bottles, brandy bottles, tequila bottles and other spirit. We emboss or engrave client’s brand name or logo on the glass directly, which means the mold is owned by the distillery.

- Electroplating brings a glossy and bright feeling for glass bottles, this kind of bottles are usually in high cost, and for top grade markets.

Shipping/Freight Information

As one of the biggest glass bottle factory in China, we supply sufficient stock for hot sale bottles, mostly are our standard glass bottles. So, the 7-10 days delivered urgent orders are available for hot sale seasons, like Christmas sale and New Year sale.

- With over 10 years’ experience in glass bottle manufacturing, we have developed thousands of glass bottle models. We have different kinds of bottle designs for client’s choice, mostly clients can find their favorite glass bottles from HIKING exist bottles, which are ready mold. The delivery time for such orders are 25-30 days.

- Some distillery companies own their exclusive liquor bottles. In this way, if you provide us the glass bottle drawing, or glass bottle sample, even a glass bottle picture, we will develop or copy a same glass bottle. The lead time for mold is 15 days.

Glass Bottle Packaging

- Standard carton packaging is used for glass bottles in printing. There is clapboard to avoid friction.

- Pallet packaging is easy handling way for glass bottle loading and unloading. It is also the most economic packaging method for spirit bottles

- Custom colored boxes packaging is the most complicated glass bottle packaging. Clients provide the box artworks, glass bottle company provide bottles and boxes, which are reusable after filling.

TIPS of GLASS BOTTLES

Glass bottle coating and hot coating. Thermal coating is performed after bottle molding and before annealing. After the molded glass bottle is slowly cooled to 500-600°C, a metal coating agent (such as tin oxide, titanium oxide, tin chloride, etc.) is sprayed on the surface of the container to form a protective film with a certain thickness, and the surface strength is enhanced 30%, meanwhile, it allows the bottle to withstand long-term water flushing and washing.

Cold coating. Cold coating is to spray the monostearate, polyethylene, oleic acid, silane, silicone or other polymer emulsion into a mist after the glass bottle is annealed, and adhere to the surface of a glass bottle with a certain temperature (the temperature of the bottle is Spray coating material, approximately 21-80°C, forms a protective layer with wear resistance and lubricity.

Frosting. Frosting is the spraying of carbon tetrachloride during the cooling process of the glass bottle, or the introduction of sulphur dioxide in the annealing furnace, both of which can react with the alkaline oxide on the surface of the bottle to precipitate sodium ions on the glass surface to form mirabilite particles. (ie, turbid white Na2SO4). After flushing with water, the chemical stability of the surface is enhanced due to the reduction of alkalinity.

Surface silicone coating treatment. The use of silicone evaporation coating on the glass surface or impregnation with silicone can form organopolysiloxane hydrophobic film and polymerization (Si02). The silicon oxide film is connected to the glass surface through a common silicon-oxygen bond. After heat treatment, the organic group will volatilize and the remaining silicon oxide film can be filled in the crack. The hydrophobic property can avoid the diffusion of the active medium in the crack and heal the surface crack (commonly known as heterophasic healing), not only the glass strength and the chemical The stability is greatly improved, and the glass has special optical properties and impact resistance. The commonly used organic silicon solutions include methyl fluorosilane, dimethyl dichlorosilane, diphenyl difluorosilane, and phenyl trichlorosilane. The thickness of the polymer film on the surface of the container is 0.005 mm, and its compressive stress increases by 10-12 Pa under the standard weight of the container. With the same internal pressure, the weight of several non-returnable standard glass bottles can be reduced from 420g to approximately 300g. The weight of glass bottles has been reduced by 25% to 30%. At the same time, since the coated film is very thin, the reflow of the glass container will not cause any environmental problems. Therefore, the online polymer coating container can be incorporated into the standard recycling process.