That "great price" per bottle might not be…

Chiedi agli esperti: Le vostre 10 domande principali sulle bottiglie all'ingrosso personalizzate, con le relative risposte

Buying bottles in bulk for your brand can be confusing. We asked our experts to give you straight answers to the most common questions.

1. How much more expensive are custom bottles?

This is the biggest factor for most businesses.

-

Stock Bottles: These are ready-to-ship bottles. They are the cheapest option to start with and you can order small amounts. The downside? Your product will look like others on the shelf.

-

Custom Bottles: You pay a high one-time fee to create a unique bottle shape (a “mold”). This is a big upfront cost ($1,500 to $2500+). However, the cost per bottle becomes much better when you order large amounts. The benefit is a unique look for your brand.

Our Advice: Think of the mold cost as a long-term investment. If you sell your product for years, that initial cost is worth it for a bottle that is only yours.

2. What is the smallest order I can place for custom bottles?

This is often the main challenge.

-

For Stock Bottles: You can order as little as a few hundred units.

-

For Custom Bottles: Because of the mold cost, you usually need to order a lot to make it worthwhile. Expect minimum orders of 6,000 to 50,000 bottles.

Our Advice: Ask the supplier for the mold cost e the price per bottle at different quantities (like 10k, 25k, 50k) to see the full picture.

3. How long will it take to get my bottles?

Plan ahead—this isn’t a fast process.

-

Quote & Design: 1-2 weeks

-

Mold Creation: 3-4 weeks (the longest step)

-

Production: 4-6 weeks

-

Shipping: 4-8 weeks (by boat from overseas)

Total Time: You should expect the whole process to take 3 to 5 months.

Our Advice: Start talking to suppliers at least 5 months before you need the bottles. This prevents rush fees and delays.

4. Which material is right for my product: glass, plastic, or aluminum?

The best choice depends on your product and brand image.

-

Glass: Feels high-end, effectively protects taste and scent, and is easily recyclable, eco-friendly too. But it’s also heavier and can break.

-

Plastic: Light, hard to break, and less expensive. It’s very flexible for design, but not eco-friendly. It can feel less premium, but using recycled plastic is a good option.

-

Aluminum: Light, strong, and completely recyclable. It has a modern, cool feel, great for drinks and some creams.

Our Advice: Tell your supplier what’s inside the bottle. They can help you pick the best material to keep your product safe.

5. What can I change to make the bottle my own?

You have many options.

-

Color: Any color you can imagine for glass or plastic.

-

Shape: The most expensive custom part—you can create a totally new shape.

-

Embossing: Adding a raised logo or text for a premium, tactile feel.

-

Printing: Putting your label art directly on the bottle.

-

Cap: Choosing the type of closure (Cork, screw cap, etc.).

Our Advice: Using embossing on a standard bottle shape is a cost-effective way to achieve a custom, high-quality look and can show your brand well.

6. How do I know the bottle will work with my product?

This is a very important technical question.

You must tell your supplier what is in your product. Key things they need to know:

-

Is it acidic?

-

What are the main ingredients?

-

Is it thick like lotion or thin like juice?

-

Will you fill it into the bottle while it’s hot?

Our Advice: Ask for compatibility testing. The supplier can put your product in sample bottles to check for leaks or changes over time.

7. What’s the difference between a prototype and a final sample?

Don’t mix these up—it’s an expensive mistake.

-

Prototype: A model (often 3D-printed) to check the shape and feel. It is not the final bottle.

-

Production Sample: The first bottles from the real mold. This is the final material, color, and size. You must approve this before the full order is made.

Our Advice: Never let the factory make your whole order until you have approved a production sample.

8. Can I buy bottles from one company and caps from another?

Yes, but we don’t recommend it.

If you do this, you are responsible for making sure the caps fit and seal perfectly. A bad fit can cause leaks and ruin your product.

Our Advice: For a guaranteed fit, buy your caps and bottles from the same supplier. At Hiking Glass, we can provide glass bottles and caps together and make sure them fit well.

9. What other costs should I expect?

The price per bottle is just the beginning.

-

Mold/Tooling Fee: The main cost for custom orders.

-

Shipping: Cost for boat freight, insurance, and import taxes.

-

Warehouse Fees: Cost to receive and store the pallets.

-

Setup Fees: For extra services like printing on the bottles.

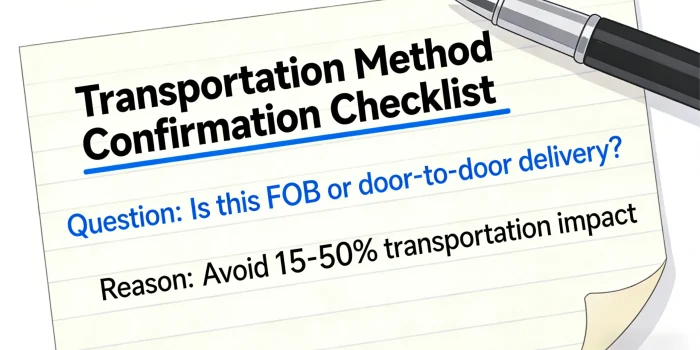

Our Advice: Ask the supplier for a “landed cost” quote. This includes everything to get the bottles to your door. At Hiking Glass, we can provide door-to-door service, from our factory to your warehouse.

10. How can I make my bottle project more eco-friendly?

Customers now expect this.

-

Material: Use glass material.

-

Lightweighting: Use less material to make the bottle and reuse it.

-

Refill System: Sell a nice, permanent bottle once, and then cheaper refills later.

-

Supplier Choice: Work with a supplier that has strong environmental practices. Trust Hiking Glass is your good choice.

Our Advice: Be specific. Ask the supplier what percentage of recycled material they use in their bottles.

Hiking Glass, produttore leader di bottiglie di vetro nella vivace industria vetraria cinese, è orgogliosa di presentare oltre 15 anni di esperienza nell'esportazione e un team dedicato di oltre 500 artigiani qualificati. Siamo specializzati nella realizzazione di bottiglie di vetro personalizzate in base alla visione del vostro marchio, offrendo un'ampia gamma di opzioni per vari alcolici, tra cui vodka, whisky, gin, rum e tequila.