Want a High-Quality Custom Whiskey Bottle? What Finishing…

When Buying Glass Bottles Wholesale, Ask About These“Hidden Costs”Besides the Unit Price!

That “great price” per bottle might not be so great after all. Many businesses jump into glass bottles wholesale orders focusing only on the shiny unit price. But smart buyers know to ask about these 6 hidden costs that can blow your budget:

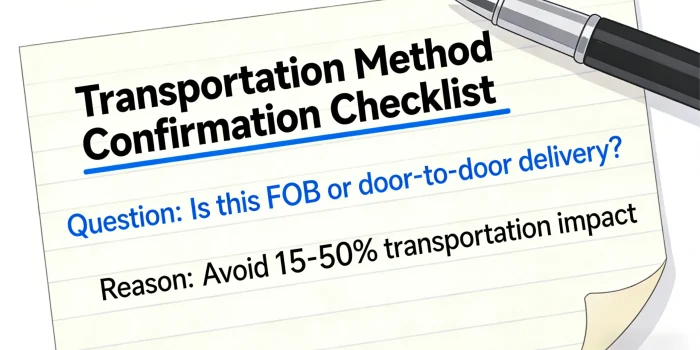

1. Transportation Fees: The Silent Budget Killer

Distance = dollars. Shipping heavy glass bottles across countries (or oceans) adds massive freight fees. Always ask:

- Is this price FOB (you pay shipping) or delivered?

- What’s the estimated freight cost to my warehouse?

- Are there fuel surcharges or peak season fees?

Real case: A brewery paid 4,200 in shipping – adding 18% to costs!

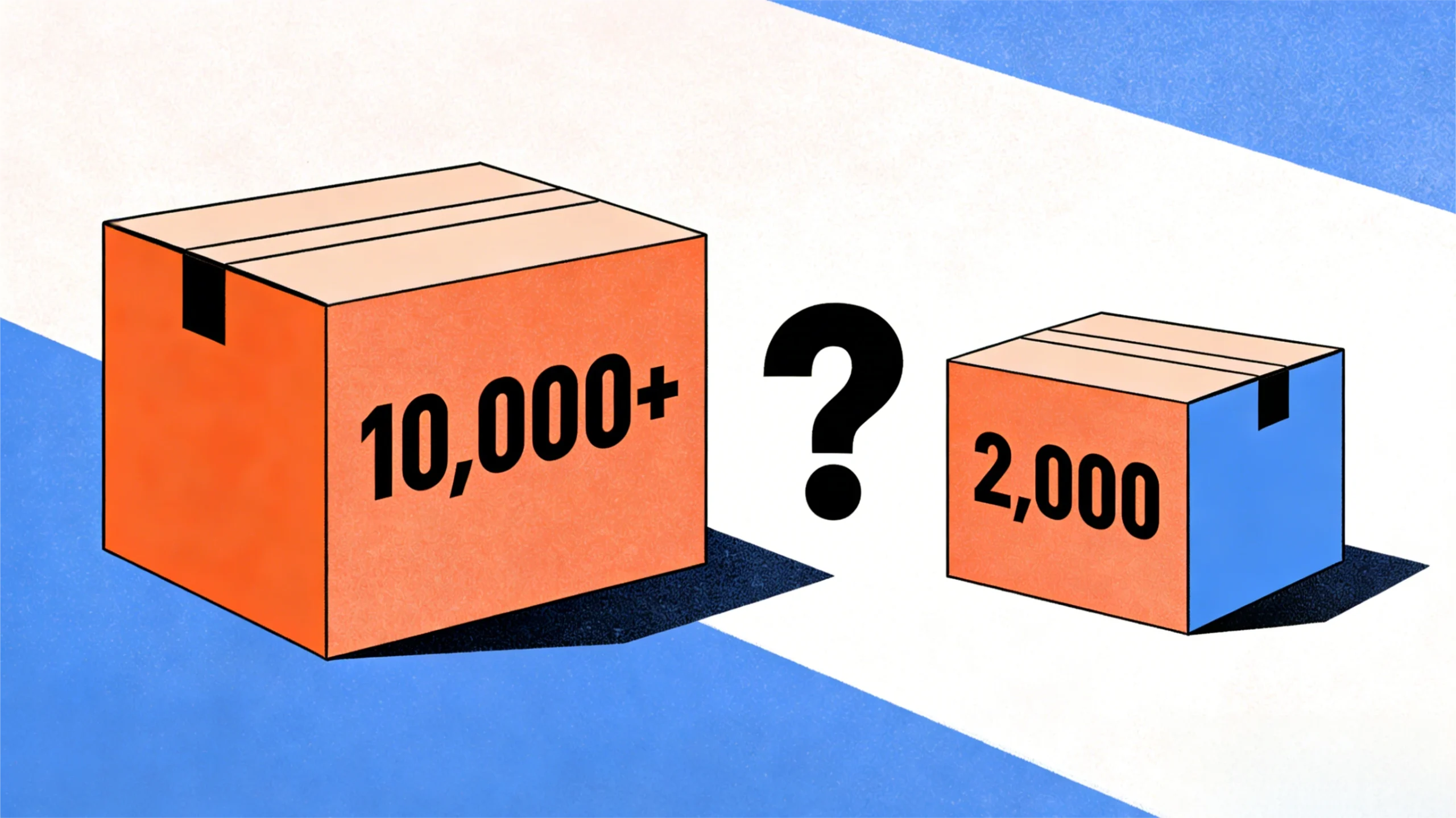

2. Minimum Order Quantity (MOQ) Matters More Than You Think

Suppliers love large orders. You might get a low per-bottle price only if you buy 10,000+ units. But what if you only need 2,000?

- Negotiate smaller MOQs for samples or first orders

- Ask about mixed cartons (multiple bottle sizes in one shipment)

- Confirm if MOQ is per SKU or total order

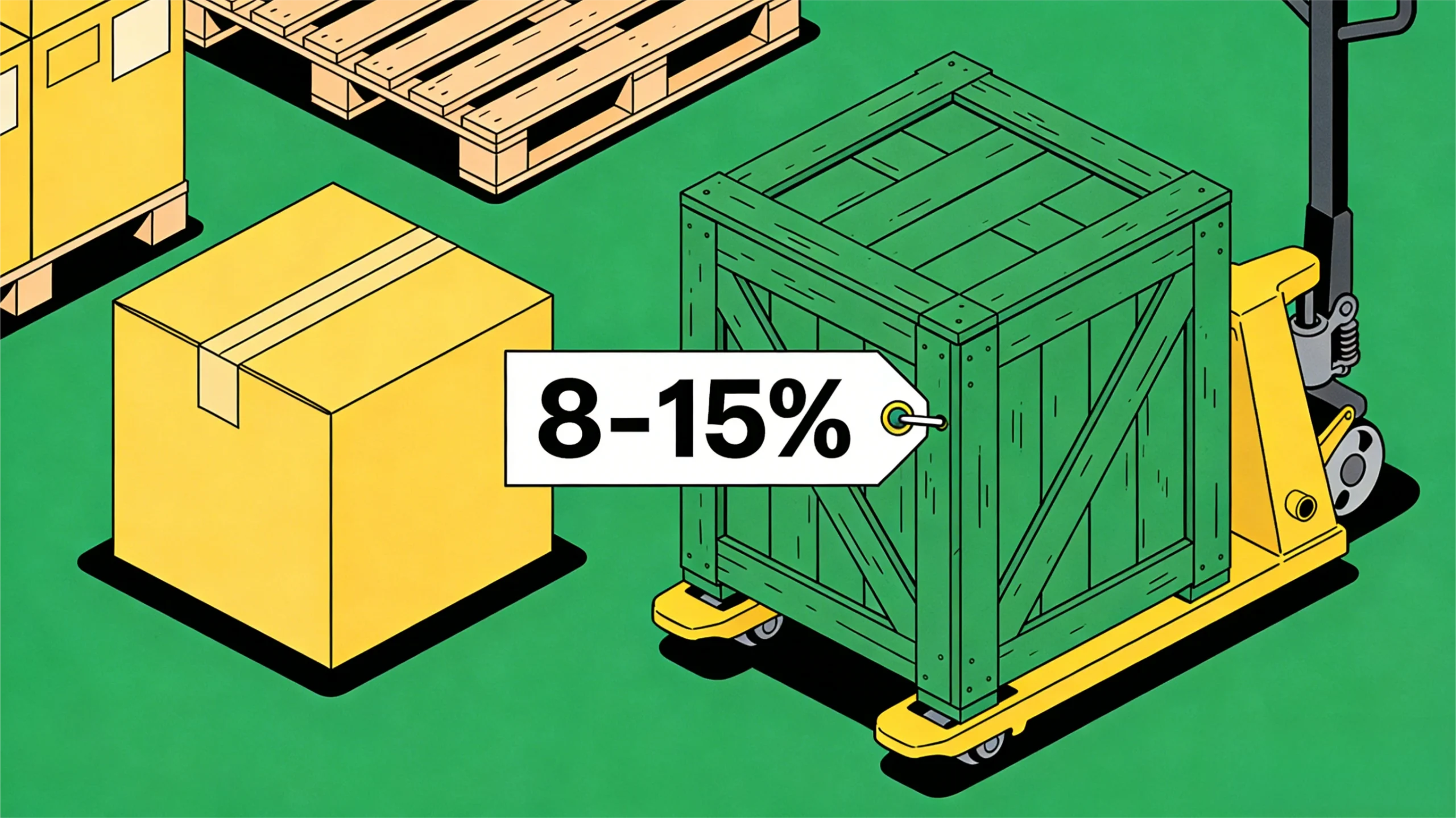

3. Glass Bottles Wholesale Packaging Requirements

How bottles are packed affects cost and safety:

- Standard carton vs. heavy-duty crates? (Cost difference: 8-15%)

- Palletizing fees: 1240 per pallet

- Labeling per box: 0.100.50/unit

Tip: Request “floor loaded” containers to skip pallet costs if you have forklifts.

4. Customization Charges You Might Miss

That beautiful amber color or custom embossing isn’t always free:

- Color changes: +7-20%

- Private mold fees: 1,5008,000 (one-time)

- Screen printing: +0.150.60/bottle

- Minimum design fees even for tiny logos

Ask: “What’s included in the base price?”

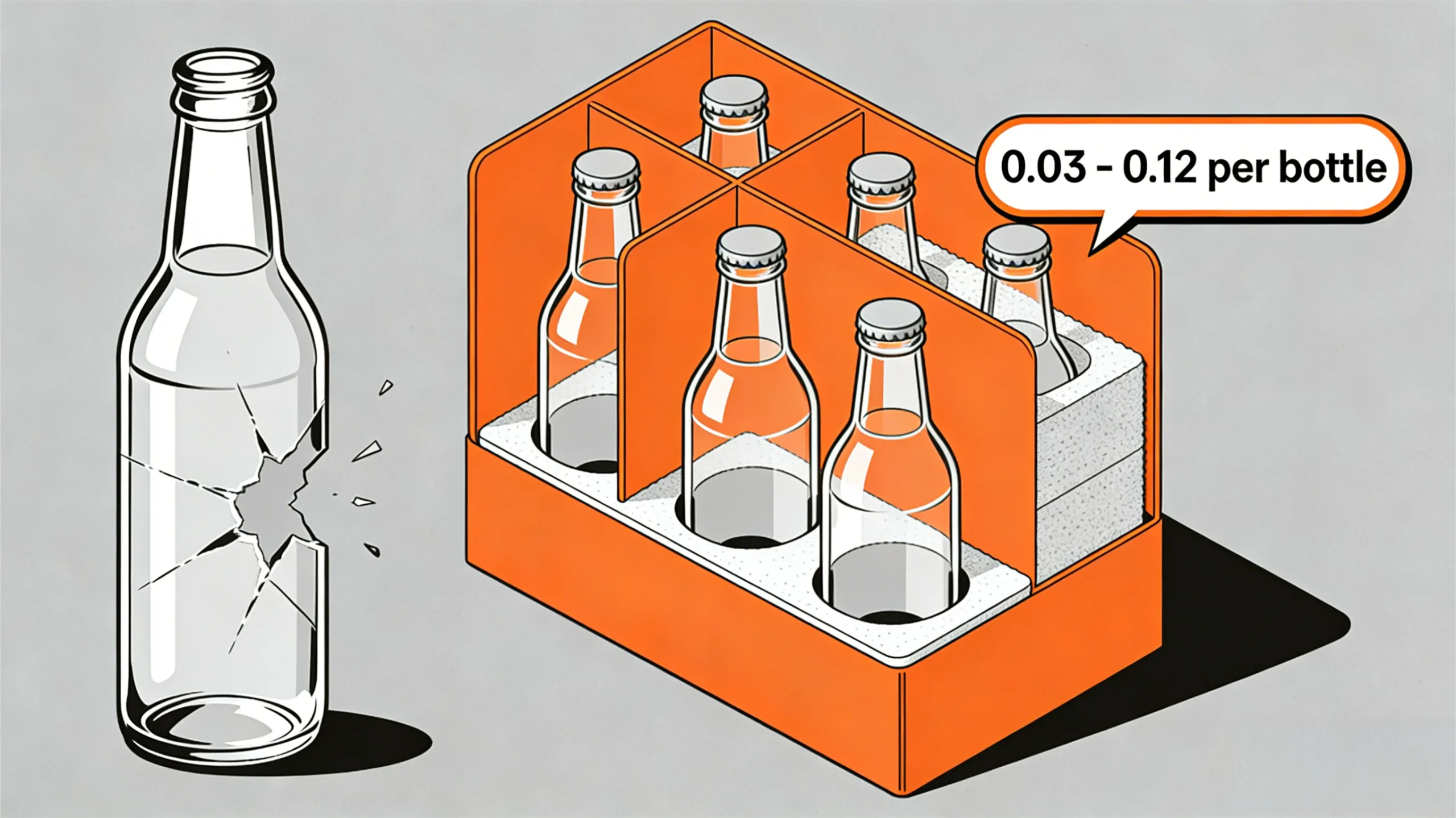

5. Protective Packaging Essentials

Glass breaks. Who pays for the armor?

- Separator inserts: 0.030.12/bottle

- Extra corner padding: +5% to carton cost

- Climate-controlled shipping for sensitive labels (+12-30%)

Skip this = risk 2-15% breakage!

6. Payment Terms That Pinch Cash Flow

- Wire transfer fees: 1545 per transaction

- 30% deposits on custom orders

- Letters of credit charges (1-3% of order value)

Always request net-30 terms to preserve cash.

7. Quality Control & Rejection Risks

Finding defects after delivery costs YOU:

- Inspection fees: 200500/shipment

- Return shipping for rejects: $500+

- Production delays from bad batches

Solution: Demand pre-shipment photos/videos and a clear QC policy.

Your Action Plan:

Print this checklist for your next glass bottles wholesale inquiry:

| Question to Ask | Why It Matters |

|---|---|

| “Is this FOB or delivered?” | Avoids +15-50% shipping shock |

| “What’s the exact MOQ?” | Prevents overstocking |

| “Break down packaging fees” | Reveals 0.100.80/bottle adds |

| “Show QC test reports” | Reduces breakage risks |

| “Any mold/deposit requirements?” | No surprise $5,000 charges |

The Bottom Line

A 0.80 with hidden fees. Always get a detailed quote showing every cost – before you sign anything. Smart questions protect your profit!