Price is just the starting point. The real…

The Whole Process of Glass Bottle Making: Unveiling the Secret of Superior Glass Bottle Production

The Whole Process of Glass Bottle Making: Unveiling the Secret of Superior Glass Bottle Production

How are superior glass bottle production?From a variety of beverage bottles, eye-catching perfume bottles, to ordinary food jars, glass bottles have a wide range of uses. However, the manufacture process behind them is often overlooked. Let’s take a journey into the world of glass bottles to uncover the mysteries of their production process.

Selection and Preparation of Materials:The first step in glass bottle production

First, we need to explore the main ingredients for making glass bottles. Quartz sand, limestone, and alkali metal sand are essential materials for creating glass bottles. These materials must be carefully prepared and mixed to ensure the quality of the glass bottles produced is excellent, and the transparency is high.

Melting Process

Next, we move on to the melting process of glass. The ingredients melt at high temperatures, forming molten glass. This procedure calls for precise temperature control and timing. Only at the right temperature and timing can the ingredients completely dissolve, forming uniform and bubble-free glass.

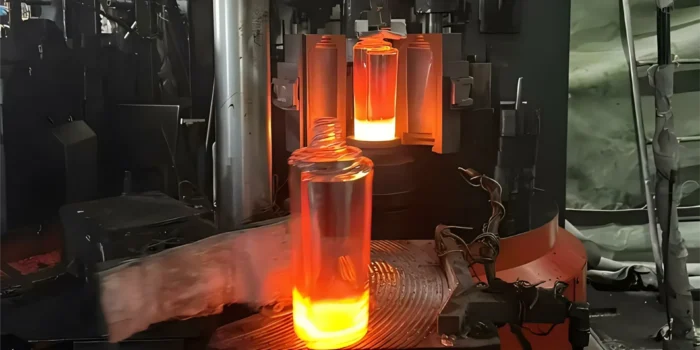

Formation Stage of Glass Bottles

Then, we arrive at the formation phase of the glass bottles. At this stage, the carefully controlled molten glass is injected into pre-set molds. The shape and size of the molds determine the shape and size of the glass bottles. Due to the flow characteristics of glass under high temperatures, it can be shaped into various forms to meet different functional and aesthetic needs.

Cooling and Post-processing of Glass Bottles

The final phase is cooling and post-treatment of the glass bottles. Cooling is a slow and precise process to ensure the stability and shatter-resistance of the glass bottles. After cooling, the glass bottles still need to undergo quality inspection and cleaning to ensure their safety and flawlessness.

In conclusion, the manufacture of glass bottles is a complex process involving various fields such as materials science, thermodynamics, and mechanical design. But next time when you pick up a beverage bottle or open a perfume bottle, you may have a new understanding and appreciation of the glass bottles used.

We’ve now had a glimpse into the glass bottle’s manufacturing process. Hopefully, through this article, you’ve gained a fresh understanding of glass bottle production. Of course, this is just the tip of the iceberg. Each stage of glass bottle production has its unique and sophisticated aspects. If you’re interested in this subject, you’re welcome to explore and learn more.