That "great price" per bottle might not be…

Supply Chain challenges and Solutions in the Glass Bottle industry

Hiking Glass, a leading glass bottle manufacturer in China’s vibrant Glass Bottle Industry, proudly presents over 15 years of export expertise and a dedicated team of more than 500 skilled artisans. We specialize in crafting custom glass bottles tailored to your brand’s vision, offering a wide range of options for various spirits, including vodka, whiskey, gin, rum, and tequila.

1. Raw Material Sourcing and Availability

Challenges:

Companies need high-quality silica sand, soda ash, and limestone, but these materials are hard to get because of environmental rules and political issues. Prices and transport costs for raw materials change a lot, making planning difficult.

Solutions:

Use more recycled glass: This cuts the need for new materials and saves energy. Work with many suppliers: Get materials from different places to avoid shortages. Work with governments: Get approvals for mining and support recycling.

2. Energy-Intensive Production

Challenges:

Melting materials uses lots of energy, which is expensive. Factories using fossil fuels create pollution.

Solutions:

Upgrade furnaces: Use modern furnaces that need less energy. Switch to clean energy: Use solar or biogas to power factories. Reuse wasted heat: Capture heat from furnaces for other tasks.

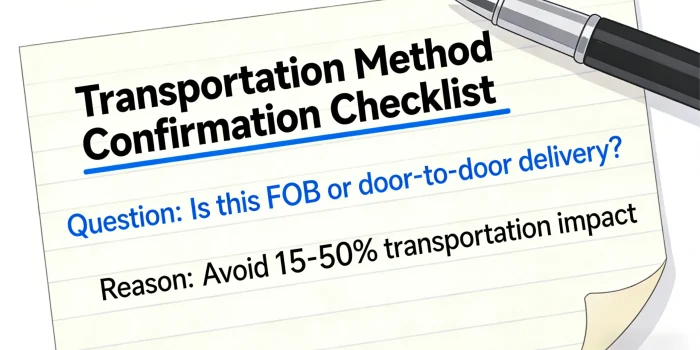

3. Fragility and Transportation Costs

Challenges:

Glass breaks easily during shipping. Shipping costs are high because glass is heavy and needs special packaging.

Solutions:

Improve packaging: Use strong but lightweight boxes and dividers. Plan better routes: Use software to find faster, safer delivery paths.

Make bottles locally: Build factories near customers to reduce shipping distances.

4. Demand Volatility and Inventory Management

Challenges:

Orders from industries like drinks or cosmetics change often. Bad predictions cause overstocking or shortages.

Solutions:

Share data with customers: Use real-time updates to plan production. Make flexible factories: Use equipment that can adjust quickly to demand changes. Keep extra stock: Store popular items to handle sudden orders.

5. Global Supply Chain Disruptions

Challenges:

Trade conflicts, pandemics, or labor shortages delay shipments.

Solutions:

Build backup factories: Have production sites in multiple regions. Use simulation tools: Test solutions for disruptions before they happen.

Train workers for multiple jobs: Prepare staff to handle different tasks.

6. Environmental and Regulatory Pressures

Challenges:

Strict pollution laws and customer demands for eco-friendly practices.

Solutions:

Reuse bottles: Create systems to collect, clean, and reuse old bottles. Capture carbon emissions: Install systems to reduce factory pollution.

Follow green standards: Get certifications to prove compliance.

7. Technological and Innovation Gaps

Challenges:

Slow use of digital tools like IoT or blockchain. Expensive automation costs.

Solutions:

Track products with sensors: Monitor production and shipments in real time. Use blockchain for transparency: Show customers where materials come from. Get funding support: Ask governments or industry groups to help pay for upgrades.

8. Quality Control and Breakage Glass Bottle Industry

Challenges:

Bottles get defects during production or break in storage.

Solutions:

Use AI inspections: Cameras and software check for flaws automatically. Use robots: Machines handle packaging to reduce human errors.

The Glass Bottle Industry can enhance resilience by prioritizing sustainability (recycling, renewables), adopting digital tools for agility, and regionalizing supply chains. Collaboration across stakeholders—suppliers, manufacturers, governments, and consumers—is critical to balancing cost, quality, and environmental goals.