Designing a Custom Liquor Bottles is one of…

How to Source High-Quality Spirits Bottles for Your Business

When you have a recipe and want to create your own brand of spirits. Determining how to package your bottle is paramount. Here’s how to help you pick the High-Quality Spirits Bottles for your business.

1. Define the needs

- Determine the type of bottle:

If it is white wine, consider whether it is the traditional porcelain bottle (suitable for high-grade wine, with good sealing and aesthetics) or glass bottle (lower cost, high transparency, suitable for mass-consumption type of white wine).

- stipulates the specification size:

There are various specifications for the capacity of wine bottles, and white wine bottles also have various capacities such as 750ml, 700ml, 500ml, 250ml, and so on. The appropriate specifications should be determined according to the company’s product positioning and sales strategy. At the same time, it is also necessary to consider whether the height, diameter and other dimensions of the bottles meet the requirements of the company’s packaging design and production line.

- understand the appearance requirements:

These include the shape of the bottle (e.g. round, square, shaped, etc.), the color (transparent, tinted, etc.) and the surface treatment (frosted, engraved, appliquéd, etc.). Appearance design should be compatible with the brand image of the product and the aesthetics of the target market. For example, high-end gift wines may need beautifully carved or hot-stamped bottles to reflect their class; while fashionable wines for young people can use novel shaped and colorful shaped bottles.

2. Finding suppliers

- utilizes online resources:

Suppliers of glass bottles can be found through search engines and B2B e-commerce platforms (e.g. Alibaba, etc.). These platforms have a large number of supplier information, including company profiles, product catalogs, customer reviews, etc., can be initially screened to meet the needs of the supplier. Meanwhile, you can also pay attention to industry forums and specialized websites to learn about wine bottle manufacturers with good reputation in the industry.

- Attend industry exhibitions:

Packaging industry exhibitions are an important way to find quality suppliers. At the show, you can directly see various wine bottle samples and learn about the latest product design and technology trends. Face-to-face exchanges with suppliers can provide a deeper understanding of their production capacity, quality control measures and service levels. For example, the China International Packaging Industry Exhibition (Sino – Pack) brings together many packaging product suppliers, including wine bottle manufacturers.

- Peer referrals:

Ask experienced peer companies for information on their wine bottle suppliers. The actual experience of peers is an invaluable reference to learn about the supplier’s real situation in terms of product quality, delivery time and after-sales service. For example, a bottle supplier recommended by a well-known winery is often proven in terms of product quality and supply stability.

3. Assessing suppliers

examine the production capacity:

- Production equipment:

Advanced production equipment is the basis for ensuring the quality of wine bottles. For glass bottle manufacturers, it is important to see whether their furnace equipment is advanced enough to ensure uniform melting of glass raw materials and high quality molding. For example, glass bottles produced by highly automated row and column machines are usually superior to those produced manually or semi-automatically in terms of dimensional accuracy and quality stability.

- Production Scale:

Find out the supplier’s annual and monthly production capacity to ensure that it has sufficient capacity to meet the company’s purchasing needs. The production scale of the supplier is especially important if the company has peak season sales peaks and needs the supplier to be able to provide a large number of bottles in a short period of time. At the same time, suppliers with large-scale production often have certain advantages in raw material procurement costs, which may also be reflected in product prices.

- Technical staff and R&D capability:

Ask the supplier about the composition of technical staff and R&D investment. Suppliers with professional technical teams and strong R&D capabilities are able to customize wine bottles according to the company’s special needs, such as developing new bottle shapes, improving the strength or sealing of bottles. For example, some high-end wine bottles may require special anti-counterfeiting technology or internal coating process, which requires suppliers to have corresponding technical R&D strength.

Inspection quality control system:

- Raw material quality:

The quality of wine bottles depends largely on raw materials. For glass bottles, it is important to know the sources and quality standards of glass raw materials. High-quality quartz sand, soda ash and other raw materials are the key to producing high-quality glass bottles. Suppliers should be able to provide inspection reports of raw materials to prove that they meet the relevant quality requirements.

- Production process quality control:

Understand the quality control measures taken by the supplier in the production process. For example, mold management, molding temperature control, annealing treatment and other aspects of the glass bottle production process directly affect the quality of the bottle. The supplier should have a perfect quality inspection process, including appearance inspection of wine bottles on the production line (e.g. whether there are bubbles, cracks, deformation, etc.), dimensional accuracy testing, physical property testing (e.g. impact strength, internal pressure resistance, etc.).

- Finished product quality inspection standards:

Suppliers are required to provide detailed quality inspection standards for finished products, and these standards should be in line with relevant national industry standards and special requirements of the company. You can ask to see the sample quality inspection report to understand its testing items, testing methods and qualified determination standards.

Check the certifications and qualifications:

- Industry certifications:

Suppliers with relevant industry certifications are usually more secure in terms of quality and management. For suppliers of wine bottles for export products, they may also need to have other international certifications, such as the EU’s food contact material certification, to ensure that the bottles meet the quality and safety requirements of the importing country.

- Production qualifications:

Confirm that the supplier has legal production qualifications, such as business license and production permit. This can ensure that the supplier is producing under legal compliance and avoid potential risks to the company due to qualification problems.

4. Sample testing

- Request for samples:

Request samples of wine bottles from suppliers after preliminary screening. When requesting samples, it should be clearly required that the specification, model and appearance of the samples should be consistent with the actual products purchased. The supplier can be asked to provide samples of several batches to examine the stability of their product quality.

- Appearance Inspection:

Appearance inspection of the samples includes the transparency of the bottles (for transparent bottles), color uniformity, surface flatness (whether there are any unevenness, scratches, etc.), and the regularity of the bottle shape (whether it is deformed or not), and so on. For wine bottles with decoration, such as decals, carvings, etc., the quality of the decoration should be checked, such as whether the decals are firm and bubble-free, and whether the carvings are fine.

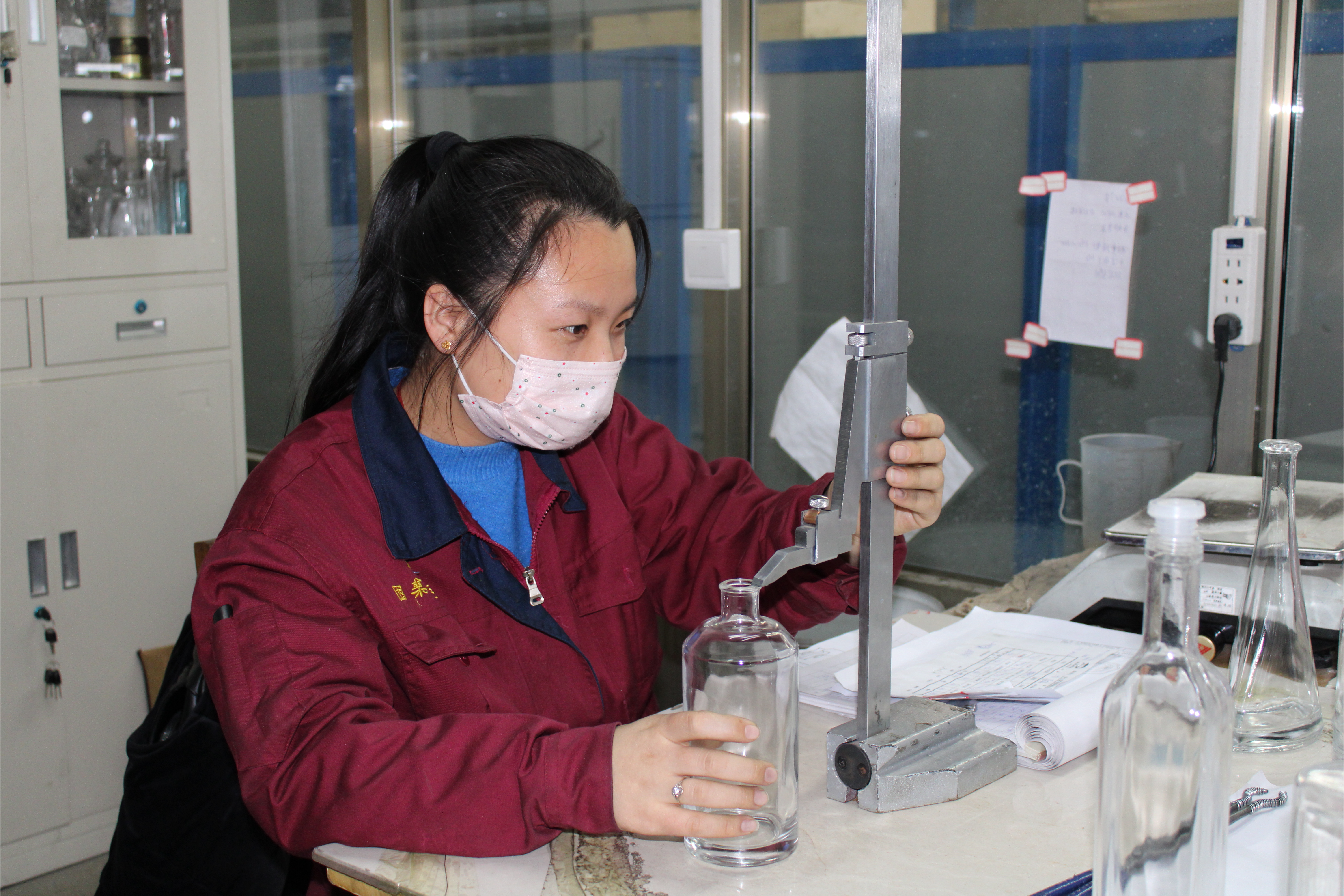

- Dimensional accuracy inspection:

Use calipers and other tools to measure the key dimensions of wine bottles, such as height, diameter, neck size, etc., to check whether they meet the requirements. Dimensional accuracy is very important for the packaging and transportation of wine bottles, as well as their coordination with accessories such as caps. For example, if the neck size of a wine bottle is inaccurate, it may lead to a poor sealing of the cap, affecting the preservation quality of the wine.

- Physical property test:

Impact strength test: The impact resistance of wine bottles is tested by simulating the impacts that the bottles may receive during transportation, loading and unloading. It can be tested by using a professional impact resistance testing machine, or by simple methods such as free-falling the wine bottle from a certain height onto a soft surface (such as a sponge mat) and observing whether the bottle is cracked or damaged.

Internal Pressure Resistance Test: For glass bottles that need to withstand certain internal pressure (such as champagne bottles, carbonated beverage bottles, etc.), internal pressure resistance test should be carried out. Use a professional pressure-resistant tester to apply a certain amount of internal pressure according to the relevant standards, and observe whether the bottles can withstand the prescribed pressure without rupture.

Sealability test: Fill the glass bottle with water or simulated liquid, place it upside down or horizontally for a period of time, and check whether there is any leakage. Good sealing is a key factor in ensuring the quality and shelf life of the spirits.

5. Price negotiation and contracting

- Price negotiation:

After ascertaining that the quality of the supplier’s products meets the requirements, price negotiation is carried out. Understand the market price level, and analyze the reasons for price differences (e.g. raw material costs, production process, brand factors, etc.) by comparing prices with several suppliers. In the negotiation process, you can try to negotiate with the supplier volume discounts, long-term cooperation preferential and other price strategies to reduce procurement costs.

- Contract signing:

Sign a detailed procurement contract, which should specify the specifications of the bottles, quantity, price, delivery date, quality standards, acceptance methods, breach of contract liability and other terms. In particular, the quality standard and acceptance method clause should stipulate in detail the company’s specific requirements for the quality of wine bottles and the procedures and methods of acceptance, in order to avoid quality disputes in the subsequent cooperation. At the same time, the contract should also stipulate intellectual property protection clauses to ensure that there is no infringement of intellectual property rights, such as the design of the bottles provided by the supplier.

6. Hiking Glass Bottle

Hiking glass bottle manufacturer with over 10 years of international trade experience. We specialize in designing and producing custom glass bottles, with a complete production process from designing to mold making. Our company has 14 production lines more than 500 skilled workers and a daily production capacity of 800,000 glass bottles.

We also offer a range of decoration options, including screen printing, decal, color spraying,frosting, and electroplating. At Heze Hiking Packging Co., Ltd.,we take pride in our commitment to providing excellent service to all customers.